Fuel pump does prime and I haven't check the battery voltage, but I'm sure its working since I have fuel on my spark plug a few days ago trying to start it.

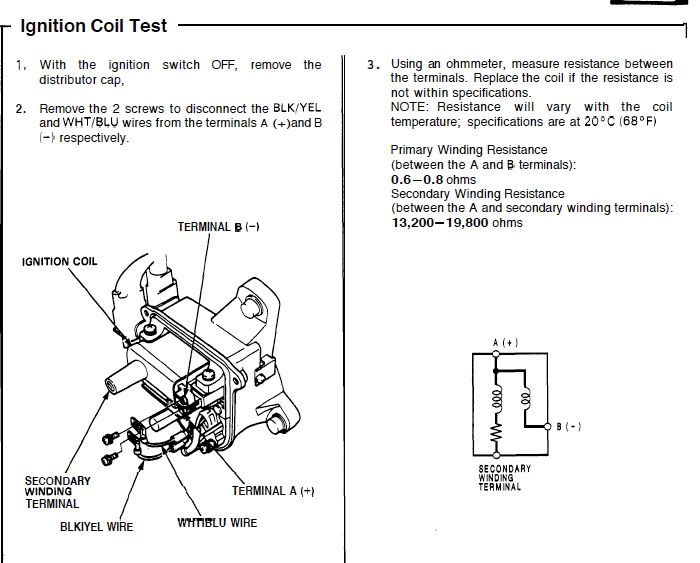

Anyways, I took the ICM and coil out today. I tested the coil primary winding and got zero not sure if I'm doing something wrong here. I got a reading around 10.88 for the secondary winding while on the car and off the car.

Brought both parts to Autozone. They got around 10 as well for the secondary winding, but not sure what they got for the primary. They told me that the secondary is a little under spec though. As for the ICM they took it to the back and said that their machine was showing it as bad. Pretty much they said I needed to replaced both parts.

Then I brought it to Advance Auto Parts for a second opinion and they tested the ICM right there in front of me. Their machine show that it is good. As for the coil they don't test coil.

Brought it to a locally owned auto parts store for a third opinion. They also tested the ICM in front of me and it show that it was good. As for the coil they got around 10 as well for the secondary winding and somewhere around zero for the primary. They said that its normal for a coil to read around 10 on the secondary and that my coil was fine as well.

What should the spec be for primary and secondary winding for a D16z6? Same as what the picture stated? Even though its a different distributor from mine.

As for my cap and rotor my computer is having trouble upload pictures, but anways the cap doesn't seem to have any crack on it. It has a little carbon, but nothing too much. The terminal under the cap feel rough and is kind white. (Look like the same white mark if you rub a rock against another rock.) Rotor seems rough as well and it has the same white marking on it. I'm not really sure what a normal distributor terminal and rotor should look compare to a worn out one.

What do you guys think it might be?