This something that I have found because I am going to buy lug nuts and I did not find any info on here about them so I did some research and this is what I found.

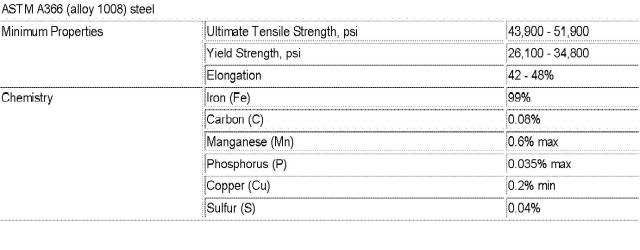

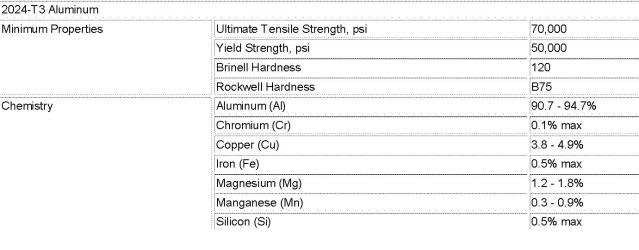

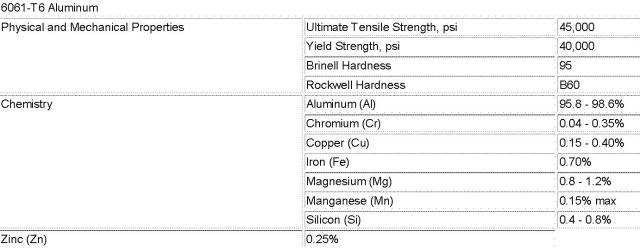

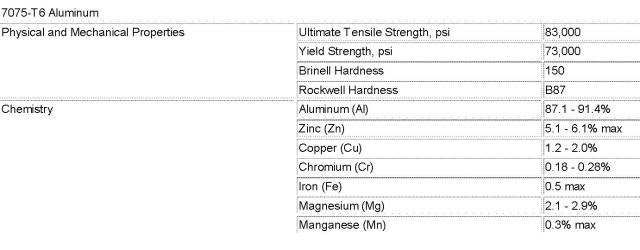

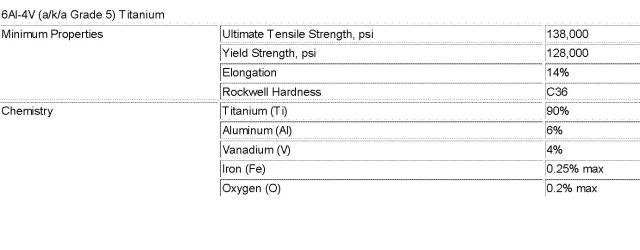

I know there are a lot of these*lug*nuts*already being offered by name brands such as Muteki, Rays, Mugen, Work and more. Of course we could’ve had just found a distributor and offered these same products to you, but we decided to go one step further and do some research on the materials that these lightweight lug nuts are being made from. We did this to see which product offered by these companies, offered the best weight to strength ratio. Of course price is always important as well.Here’s what we found and it might surprise you:- Standard steel lug nuts: This is the base line for all of our comparisons. A standard closed end steel lug nut weighs about 2 ounces or 56.7 grams. Some manufacturers who offer cool painted lug nuts made of steel try to pass this off as lightweight. Just be aware you’re getting nothing but a paint job. 2 ounces is not light. Aluminum lug nuts weigh about 0.8 ounces or 22.6 grams for a full size race lug nut.- Aluminum lug nuts: Most of the lesser expensive lug nuts and even some of the name brands use the cheaper 6061 aluminum. This aluminum has the lowest*yield*strength*of all the aluminums used to make lug nuts. As a matter of fact, 6061 has the lowest yield strength of any material used to make lug nuts. This is what you mostly find on eBay from private label vendors. I wouldn’t put these on my own vehicle.* Buddy club uses a material they call “Forged Alumite” which by the way is not a type of aluminum. This is just advertising. We aren’t sure what specific alloy they are made from. It could be either the better 7075 or the common softer 6061. At the price of the Buddy clubs it is not worth the risk.* Rays calls their product “DURA-NUT” which is made from Dura-aluminum, which is a trade name for 2024 series aluminum (look @ the chart below for the specs). It is one of the two aircraft grade aluminums, the other being 7075-T6.Notes: Duralumin (also called duraluminum, duraluminium or dural) is the trade name of one of the earliest types of age-hardenable aluminium alloys. The main alloying constituents are copper, manganese, and magnesium. A commonly used modern equivalent of this alloy type is AA2024, which contains 4.4% copper, 1.5% magnesium, 0.6% manganese and 93.5% aluminium by weight. Typical yield strength is 450 MPa, with variations depending on the composition and temper. This information was extract from Wikipedia.* Some companies offer forged aluminum lug nuts made from 7075-T6 aluminum. We feel this is the best material presently being used. It offers the best combination of weight vs. strength vs. price. Once again take a look at the property tables provided below to compare the yield strength to that of steel, titanium and other*aluminum*alloys. This is the material that our lug nuts will be made from. It has a high yield strength combined with a high hardness rating. It’s used extensively in aircraft construction along side titanium where weight and strength are the two primary concerns.- Titanium lug nuts: Finally a few companies are making titanium lug nuts. These are very expensive, especially for true grade 5 (6AI-4V) Titanium products. While the yield strength for titanium is much higher than even 7075-T6 aluminum, titanium weighs more for the same given size. Therefore, if two lug nuts have the same dimensions (which they usually do) the titanium lug nut will weigh more than the aluminum counter part. So if weight is the main consideration, aluminum still has the advantage. It has more than enough yield strength (comparable to that of a steel lug nut), and weighs the least of all of the other materials. The one area that titanium has the advantage for this application is in race environments where wheels have to be taken off and on many times. It has better fatigue resistance than aluminum in this environment of reparative tightening and loosening. The thread area is also more resistant to wear form the constant threading and unthreading that the lug nut is subjected to. For most street applications, this is an unwarranted expense.

I know there are a lot of these*lug*nuts*already being offered by name brands such as Muteki, Rays, Mugen, Work and more. Of course we could’ve had just found a distributor and offered these same products to you, but we decided to go one step further and do some research on the materials that these lightweight lug nuts are being made from. We did this to see which product offered by these companies, offered the best weight to strength ratio. Of course price is always important as well.Here’s what we found and it might surprise you:- Standard steel lug nuts: This is the base line for all of our comparisons. A standard closed end steel lug nut weighs about 2 ounces or 56.7 grams. Some manufacturers who offer cool painted lug nuts made of steel try to pass this off as lightweight. Just be aware you’re getting nothing but a paint job. 2 ounces is not light. Aluminum lug nuts weigh about 0.8 ounces or 22.6 grams for a full size race lug nut.- Aluminum lug nuts: Most of the lesser expensive lug nuts and even some of the name brands use the cheaper 6061 aluminum. This aluminum has the lowest*yield*strength*of all the aluminums used to make lug nuts. As a matter of fact, 6061 has the lowest yield strength of any material used to make lug nuts. This is what you mostly find on eBay from private label vendors. I wouldn’t put these on my own vehicle.* Buddy club uses a material they call “Forged Alumite” which by the way is not a type of aluminum. This is just advertising. We aren’t sure what specific alloy they are made from. It could be either the better 7075 or the common softer 6061. At the price of the Buddy clubs it is not worth the risk.* Rays calls their product “DURA-NUT” which is made from Dura-aluminum, which is a trade name for 2024 series aluminum (look @ the chart below for the specs). It is one of the two aircraft grade aluminums, the other being 7075-T6.Notes: Duralumin (also called duraluminum, duraluminium or dural) is the trade name of one of the earliest types of age-hardenable aluminium alloys. The main alloying constituents are copper, manganese, and magnesium. A commonly used modern equivalent of this alloy type is AA2024, which contains 4.4% copper, 1.5% magnesium, 0.6% manganese and 93.5% aluminium by weight. Typical yield strength is 450 MPa, with variations depending on the composition and temper. This information was extract from Wikipedia.* Some companies offer forged aluminum lug nuts made from 7075-T6 aluminum. We feel this is the best material presently being used. It offers the best combination of weight vs. strength vs. price. Once again take a look at the property tables provided below to compare the yield strength to that of steel, titanium and other*aluminum*alloys. This is the material that our lug nuts will be made from. It has a high yield strength combined with a high hardness rating. It’s used extensively in aircraft construction along side titanium where weight and strength are the two primary concerns.- Titanium lug nuts: Finally a few companies are making titanium lug nuts. These are very expensive, especially for true grade 5 (6AI-4V) Titanium products. While the yield strength for titanium is much higher than even 7075-T6 aluminum, titanium weighs more for the same given size. Therefore, if two lug nuts have the same dimensions (which they usually do) the titanium lug nut will weigh more than the aluminum counter part. So if weight is the main consideration, aluminum still has the advantage. It has more than enough yield strength (comparable to that of a steel lug nut), and weighs the least of all of the other materials. The one area that titanium has the advantage for this application is in race environments where wheels have to be taken off and on many times. It has better fatigue resistance than aluminum in this environment of reparative tightening and loosening. The thread area is also more resistant to wear form the constant threading and unthreading that the lug nut is subjected to. For most street applications, this is an unwarranted expense.

Attachments

-

17.8 KB Views: 24

-

18.2 KB Views: 17

-

18.5 KB Views: 19

-

17.3 KB Views: 24

-

14.3 KB Views: 18

Last edited: